1. High Efficiency & Comfort

Improved Efficiency

The below graphs highlight the improved efficiencies between the previous models compared to the KXZ standard and Hi-COP models.

High efficiency and compact design are realized by applying various advanced components.

Variable Temperature and Capacity Control

- The VTCC is a newly developed energy saving function designed by Mitsubishi Heavy Industries Thermal Systems.

- A new feature to all our KXZ ranges which provides up to 34%* energy savings in both cooling and heating mode.

- VTCC is a function specifically designed to maximise energy savings in partial load conditions throughout all seasons.

*34% energy savings are based on comparison with Mitsubishi Heavy VRV Heat pump combination systems standard inverter (38.0Hp) FDC1060KXZE1 with VTCC vs. Mitsubishi Heavy VRV Heat pump combination systems standard inverter (38.0Hp) FDC1060KXZE1 both under partial load condition.

Multiport compressor that achieves high efficiency

The new multiport discharge area in the compressor has optimized pressure control with better balancing.

The performance improvement at medium Hz has resulted in higher annual efficiencies.

Improved Heat-exchanger

With piping layout rearranged from header to heat exchanger, refrigerant distribution flow has improved and maximum energy efficiency has been achieved. Heat exchanger has improved refrigerant distribution and increased effectiveness.Furthermore due to expansion of effective heat transfer area in heat exchanger, energy efficiency has increased.

Strengthened resistance against frost

Resistance against frost has been strengthened by achieving improved heat-exchanger.

Vector control

New applied Vector control has a high efficiency and many new advanced features.

- Smooth operation from low speed to high speed.

- Smooth Sine Voltage Wave form are attained.

- Energy efficiency is further improved in low speed range.

Long-chorded 3 propeller fan with serration

Fan blade design adapted from Mitsubishi Heavy Industries aerospace division - with serrated edges that deliver increased air volume with less power input.

DC Fan Motor

Employment of DC fan motor has enabled to realize an excellent efficiency of approximate 60% higher than previous models.

Oil level control capability

Our proprietary technology of adjusting oil level for combination of two or three outdoor units has realized leveled operation rate, keeping performance of the units and ensuring long life of the system.

Capacity control

Capacity control can be set by peak cut function with RC-EX3 for better energy saving.

Five-step capacity control is available. (100-80-60-40-0%)

Compact high efficiency Heat Exchanger

- Optimizing relationship of the air flow velocity & fin pattern.

- Improvement of air distribution Maximizing efficiency of heat exchanger.

2. Design Flexibility

Indoor unit capacity connection

130% capacity connection.

Connectable indoor units

Connect up to 80 indoor units.

Wide Range of Operation

Mitsubishi Heavy VRV Heat pump combination systems standard inverter (38.0Hp) FDC1060KXZE1 permits an extensible system design considering a heating range operation under a low temperature condition down to -20˚C and a cooling range operation up to 46˚C (previous model : 43˚C).

Long Pipe Length 10 ~ 60.0Hp

Piping length has extended max height difference between indoor units up to 18m and enables us to put indoor units on extra three floors.

The furthest indoor unit: 160m or total length: 1000m contributes to system design flexibility.

Easy Transportation & Installation

Due to realization of significant reduction in size and foot print which is one ofthe smallest in the industry.

Blue Fin

Due to application of blue coated fins for the heat exchanger of new outdoor unit, corrosion resistance has been improved compared to current models.

Priority operation mode rule

User can select the following priority operation mode. (for whole system)

1. First unit’s operation mode (by default setting).

2. Last unit’s operation mode.

3. Majority operation mode (see below).

4. Master operation mode (see below).

Majority operation mode: The system is operated according to the mode selected by the majority of units in operation (whichever greater capacity between the sums of cooling mode and heating mode). The operation mode in minority is set to fan mode automatically.

Master operation mode: The system is operated according to master operation mode. When master operation mode is set at cooling mode, units selected as heating mode is set to fan mode automatically.

3. Serviceability

Easy Service

Quick and easy access to service parts by separation of compartments.

Check Operation

Closing of Service valve, crossing connection of refrigerant piping and electrical wiring, proper operation of EEV (Electrical Expansion Valve) can be checked automatically in cooling operation. This check operation can be done at 0~43ºC outdoor temperature and 10~32ºC indoor temperature by use of outdoor unit dip switch. The check should be done in one refrigerant system. It takes 15~30 minutes and avoids frequent failure by preventing careless mistakes during installation.

Monitoring Function

All series includes new feature to assist with servicing and trouble shooting.

Various data can be monitored through 3-digit or 6-digit display on the outdoor unit PCB.

Layer Construction

Thanks to control box structure with 3 layer/2 layer construction using hinge connection, service and maintenance has been made much easier for inverter components.

Back-up Operation

In the event that one unit has a failure, the system will keep operating with the other good units.

Advantages of Mitsubishi Heavy VRV Heat pump combination systems standard inverter (38.0Hp) FDC1060KXZE1

- Connect up to 80 indoor units/up to 130% capacity.

- High efficiency with COP (in cooling) up to 3.7.

- These units employ DC inverter multiport compressors with concentrated winding motor.

- Industry leading total piping length up to 1000m and a maximum pipe run of 160m.

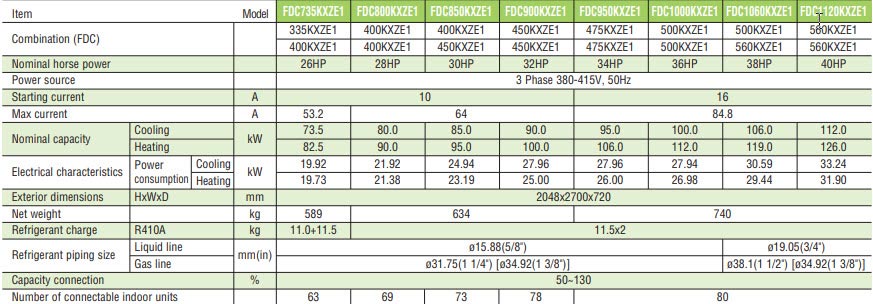

Specifications

1. The data are measured under the following conditions(ISO-T1). Cooling: Indoor temp. of 27ºCDB, 19ºCWB, and outdoor temp. of 35ºCDB. Heating: Indoor temp. of 20ºCDB, and outdoor temp. of 7ºCDB, 6ºCWB. Piping length is 7.5m.

2. Sound pressure level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

3. [ ] : Pipe sizes applicable to European installations are shown in parentheses.