Advanced technology for optimal energy-saving performance

By combining advanced hardware and software technologies to save energy during actual operation and especially when combining VRV, VRT, and VAV technologies, Daikin has achieved both energy-saving and optimal air conditioning.

Smart VRT control (fully automatic energy-saving cooling system)

Optimal for supplying only essential indoor units

Daikin has developed Smart VRT control by integrating airflow control (VAV: Effective Airflow) for Smart VRT-controlled indoor systems, as well as by optimizing the compressor speed by measuring the optimum load for the entire device and the optimum coolant temperature based on data obtained from indoor units. Combining airflow control reduces the compressor load and minimizes operating losses based on tight control. THE Smart VRT feature ensures efficient energy-saving and comfortable air conditioning to meet real-world operating conditions.

- Control overview (traffic control in the system)

The automatic refrigerant controls for energy saving are applied differently depending on the connected indoor units.

Optimal use of Smart VRT control and VRT control

The efficiency of Smart VRT control and VRT control will be proven when all indoor units are operating under low load conditions.

A low load condition is when the room temperature reaches the set temperature.

For this reason, please note the following to maximize energy efficiency.

- When selecting an indoor unit

The indoor units are installed in the same system so that it can operate under the same conditions.

Energy efficiency is reduced for the types of installations as shown below.

For example:

- A load imbalance occurs because an indoor unit in the same system is installed near a room wall or near a door.

- Hours of operation are different for indoor units.

- Energy efficiency decreases when the set temperature of an indoor unit has been dropped excessively during cooling or increased excessively during heating.

- The wind speed setting is selected in the "Auto" mode during control by Smart VRT.

Optimal energy saving during low-load operation

The key to saving energy is achieving high performance when operating at low loads.

With data obtained from actual operation, Daikin found that air conditioning systems operate at loads of 50% or less for about 80% of its annual uptime.

It has encouraged us to create new technology to boost energy efficiency while running at low loads. Daikin VRV A series is then born to lift the energy efficiency standard.

*Main considerations when running consistently at a load of 50 percent or less.

- Since the VRV can operate separately, the air conditioning shut off in unoccupied spaces, such as meeting rooms, private rooms, and storage rooms.

- The estimated maximum number of people has not reached when designing.

- There are uninhabited areas such as office buildings.

New scroll compressor *

Refrigerant leakage shall reduce during a low load operation

Operational power loss due to coolant leakage reduced due to the exclusive back-pressure management system to ensure effective operation under low load.

Advanced oil temperature control

Redundant power consumption can minimize

The efficient oil temperature control reduces standby power consumption by up to 82.7% * annually compared to conventional models. The backup energy needed to heat oil, which typically consumes significant power, is minimized when the air conditioning system stops working.

The function of automatic refrigerant charging

Contribute to optimal operating efficiency, higher quality, and easier installation.

Optimize efficiency

The refrigerant auto-refilling function automatically determines the optimum amount of refrigerant that needs to be loaded. This function helps prevent under-load or energy loss due to excess or shortage of refrigerant.

Easy installation and high quality

The refrigerant auto-refilling function automates the proper refrigerant charge and closes the stop valve just by pressing the button after a pre-charge.

Simplifying the installation eliminates the refrigerant shortage or excess due to errors in calculation, results in higher installation quality.

VRV IV:

- Calculate the required amount of refrigerant from the design drawing.

- Recalculate the required amount of solvent-based on the finished drawing.

- Refrigerant charge.

- Regularly check the amount of solvent on the scale.

- Complete by closing the stopper after the solvent can be loaded.

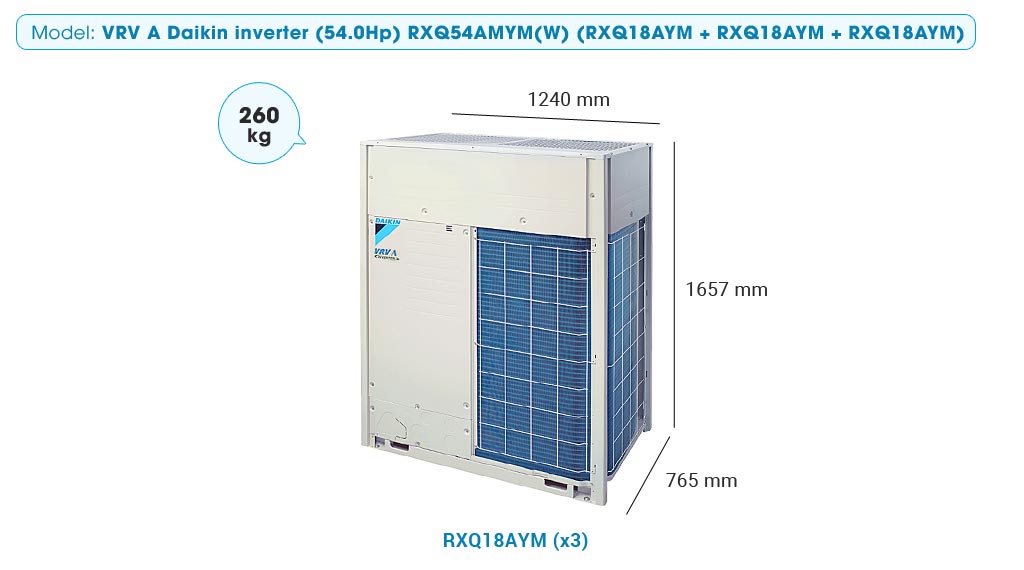

Dakin VRV A combination systems inverter RXQ54AMYM (W):

- Calculate the required amount of refrigerant from the design drawing.

- Refrigerant pre-charge *.

- Automatic solvent filling operation starts.

Automatically completes the filling of the filler with the appropriate volume.

Do not need to oversee the filling process.

Do not need to recalculate the amount of added solvent for minor or local changes.

Even if refrigerant leakage occurs from the inner pipe after installation, An sufficient volume of refrigerant can charge without needing to calculate the required quantity.

Restarting the automatic refrigerant charge operation again will ensure optimum performance and installation quality is maintained.

* The refrigerant is pre-loaded based on the working condition, they are certain situations when the refrigerant does not need to be pre-loaded where the necessary volume of refrigerant is 4 kg or less.

High reliability

New inverter printed circuit board (PCB)

The control functions of the Inverter technology implemented into the printed circuit board. Improved efficiency and decreases the number of modules and the scale of the board size.

- New waveform management increases voltage supply deviation tolerances. And if the power source is irregular, the excess current will stopped and service will begin.

- The reliability of the inverter printed circuit board increased by moving the compressor capacitor to the film capacitor.

Convenient

Low operating noise

Improved cooling performance eliminates operational noise.

High air volume, high static pressure, and low noise: Advanced analytical technologies are applied to optimize fan design for increased airflow and high external static pressure.

Quiet night operation: For outdoor areas where noise is limited for devices, Daikin VRV A RXQ54AMYM (W) outdoor unit can meet that requirement thanks to its ability to work with low noise. Auto quiet operation at night will start after the outdoor temperature reaches its highest for 8 hours * 1 and remains continuously for the next 9 hours * 2 until the regular service has restored.

*1. 8 o'clock is the default setting. Set up 6 hours, 8 hours, or 10 hours.

*2. 9 o'clock is the default setting. Set up 8, 9, or 10 hours.

*3. In the case of a 10HP outdoor unit.

Compact design with high efficiency

Highly integrated heat exchanger

4-sided heat exchange ensures a large heat exchange area. So improves heat exchange efficiency without increasing size.

Optimized internal design to ensure airflow stability

The electrical components have been shrunk and placed in the dead space of the air intake to reduce interference with airflow.

Easy maintenance

The electronic components are located at a reasonable top to help shorten the machine maintenance process. Besides, the front heat exchanger can be used efficiently to increase its efficiency.

Adequate cooling for electrical components

RXQ54AMYM (W) is designed with an electrical box positioned above between low and high-pressure areas. This architecture allows the greatest airflow from low pressure to high pressure due to a higher pressure differential.

Eliminate resistance

Without affecting the fan's air flow, the redesigned upper electrical components take advantage of dead space. So eliminates the suction.

High safety when the ambient temperature is high

It is possible to keep the operation stable even at high ambient temperature by cooling the inverter power module. So helps to maintain the air-conditioning capability and reduce the failure rate.

ODM engine

It is possible to keep the operation stable even at high ambient temperature by cooling the inverter power module. So helps to maintain the air-conditioning capability and reduce the failure rate.

Advantages of ODM:

Thanks to the large rotor diameter,

- Big torque of the same electromagnetic force.

- The revs are steady at all speeds, capable of working at low speeds.

Multiple options for the installation site

Long pipeline limit

The long pipeline length makes the design more flexible, suitable for large buildings.

When connecting with VRV indoor unit only

When connecting a mixture of VRV indoor units and residential indoor units

Connection rate

connection capacity up to 130%.

High external static pressure

RXQ54AMYM (W) achieves high external static pressure up to 78.4 Pa, ensures efficient heat dissipation, and keeps the unit running stably in a decentralized or centralized layout.

The test operating system is more accurate and stable

Efficient automatic inspection operation

RXQ54AMYM (W) complex combines an efficient and simple operation of inspection, not only speeding up the installation process but also improving the quality of the installation on site.

- Automatically check the wiring between the outdoor unit and the indoor unit to see if the wiring is faulty.

- Automatically check the status of the stopper in each outdoor unit to ensure the air conditioner operates smoothly.

- Determine pipe length to optimize operation.

Simplify operations and after-sales service

Information display by the LED screen

RXQ54AMYM (W) uses 7-segment LEDs to display system operating information, enables the display of operating status, facilitates operation and implementation of the following services.

Advanced control PC circuit board

SMT technology *

SMT technology applied to the entire computer control board improves anti-interference properties.

Protect your computer's control board against the effects of sand and wet weather.

I-demand feature

Power consumption limits are set correctly with 11 levels. Power reduction should be carried out on a case-by-case basis.

* Install on the board of the outdoor unit.

Wide operating temperature range up to 49 ° C

The wide operating range of RXQ54AMYM (W)helps to limit installation location restrictions. The operating temperature range for cooling can realize when the outdoor temperature goes up to 49 ° C. Allows operation even under high-temperature conditions.

Automatic alternating operation

When starting up, RXQ54AMYM (W) will automatically activate the alternating operation mode to ensure balanced uptime of each outdoor unit to increase equipment life and operate smoothly.

Dual preventive operation

RXQ54AMYM (W) is enhanced with dual redundant operations, ensuring maximum air conditioning in this area by emergency activation of operating functions backup even when something goes wrong in an air conditioning system. In the case of a failure, the emergency operating mode triggered, allowing the remaining device to run beyond a limit.

Backup machine operation feature: If one of the systems in the integrated outdoor unit configuration fails, the remaining outdoor systems will perform an emergency before the fix accomplish.

Features for backup compressor operation: The outdoor units equipped with two compressors. Even if one compressor malfunctions, another will operate in an emergency, reducing the risk of shutdowns due to compressor failure. (Capacity will keep during standby operation)

Easy maintenance

Các thành phần điện tử nằm ở vị trí hợp lý phía trên giúp rút ngắn quá trình bảo trì máy. Hơn nữa, bộ trao đổi nhiệt ở phía trước có thể được sử dụng hiệu quả để cải thiện hiệu suất của nó.

Strong corrosion resistance model

Anti-corrosion and maximum performance

Outer shell

Multiple coatings for extreme durability: Use hot-dip galvanized - aluminum - magnesium steel sheet to resist strong corrosion, with a 4-layer coating for greater durability.

Corrosion resistance verified by reactive reaction test: Although the previous anti-corrosion model rusted, the outer shell of the RXQ54AMYM (W) outdoor unit complex showed no signs of corrosion in either experiment.

The heat exchanger (Wing)

Anti-corrosion technology: aluminum wings of RXQ54AMYM (W) developed with a thicker anti-corrosion coating include two additional layers.

High-performance technology:

- The aluminum wings are 21% thicker.

- The new aluminum wings are 21% thicker to maintain performance.

- Automatic coating line: To prevent the difference in coating thickness due to manual operation, an additional coat is fitted on the latest automatic assembly line, maintaining accuracy and high quality.

Maximum long life

Only the outer cover and wings are 3rd party certified for durability.

Corrosion resistance test obtained UL Certificate (Passed high resistance to corrosion grade C5 defined in ISO 12944-6: 2018.)

The new model resists salt corrosion, maintains performance, and reduces life cycle costs significantly.

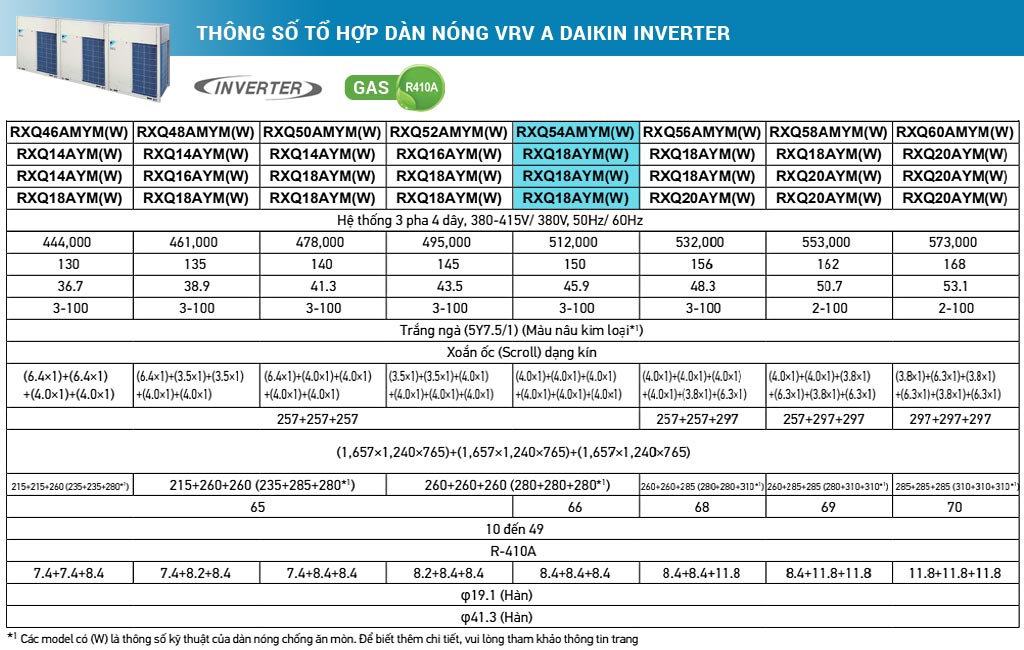

Specifications